Call : 08037301127

Aleph Industries [INDIA] Pvt Ltd.

GST : 09AATCA4877F1Z2

GST : 09AATCA4877F1Z2

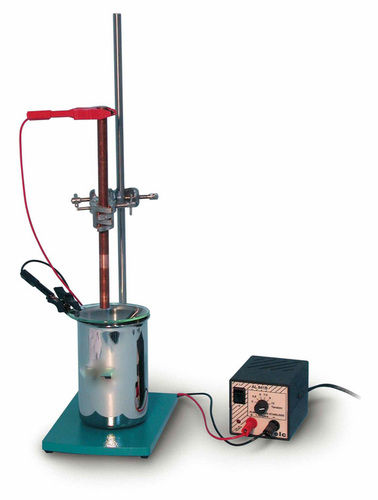

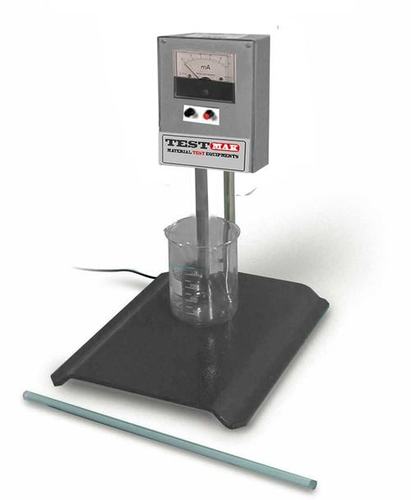

Specialized in making Lab Testing Machine, Lab Testing Equipment, Air Circulating Oven, Stainless Steel Water Bath, Laboratory Oil Bath, Digital Hydrostatic Pressure Testing Panel, etc..

- New Arrivals

- Featured

About Us

On the basis of technology, we, Aleph Industries [India] Pvt Ltd. have grown at a rapid rate and acquired a wide customer base. We are a manufacturer and supplier of Stainless Steel Water Bath ,Laboratory Oil Bath, Deep Cooling Chamber, Digital Water Bath and many more products. The components used in the making of our products are robust and not prone to corrosion.

Our mission is to serve the customers in the best possible manner with the best products. We are working hard in the same direction and in this journey, we are supported by dexterous professionals. The taskforce that we have hired, keeps itself updated with the new advancements so that they can help us manufacture assortment with respect to the same.

We are leaving no stone untured to strengthen our bond with customers and maintain a leading reputation in the market. Our company is happy to see that the customers are liking our products, working approach and policies. We promise that we will never let our customers feel down and will never step back from working hard to satisfy the clients.

Choose Us Because..

Technically Advanced

Both our offerings and production house is technically advanced and this is one of the main reasons behind the prominence of our firm. The machines used by us in our manufacturing wing are serviced and upgraded from time to time to minimize chances of failure, thereby, keeping our production process unaffected. A team of technocrats looks after the machines and keeps these in line with the modern technology.

Our entire range including Digital Water Bath, Deep Cooling Chamber, Ball Drop Test, Weighing Balance For Density Test and all other products is ultra-modern, which makes these the prime choice of the customers in the market.

On the basis of technology, we, Aleph Industries [India] Pvt Ltd. have grown at a rapid rate and acquired a wide customer base. We are a manufacturer and supplier of Stainless Steel Water Bath ,Laboratory Oil Bath, Deep Cooling Chamber, Digital Water Bath and many more products. The components used in the making of our products are robust and not prone to corrosion.

Our mission is to serve the customers in the best possible manner with the best products. We are working hard in the same direction and in this journey, we are supported by dexterous professionals. The taskforce that we have hired, keeps itself updated with the new advancements so that they can help us manufacture assortment with respect to the same.

We are leaving no stone untured to strengthen our bond with customers and maintain a leading reputation in the market. Our company is happy to see that the customers are liking our products, working approach and policies. We promise that we will never let our customers feel down and will never step back from working hard to satisfy the clients.

Choose Us Because..

- We deliver a flawless range of products that is quality checked, a number of times, before delivery.

- We charge reasonable rates for our products and accept payment by any mode that is suitable to customers.

- We follow all the rules and regulations that are predefined for the respective industry and stay updated with the change in policies.

Technically Advanced

Both our offerings and production house is technically advanced and this is one of the main reasons behind the prominence of our firm. The machines used by us in our manufacturing wing are serviced and upgraded from time to time to minimize chances of failure, thereby, keeping our production process unaffected. A team of technocrats looks after the machines and keeps these in line with the modern technology.

Our entire range including Digital Water Bath, Deep Cooling Chamber, Ball Drop Test, Weighing Balance For Density Test and all other products is ultra-modern, which makes these the prime choice of the customers in the market.

Back to top

|

ALEPH INDUSTRIES [INDIA] PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

![Aleph Industries [INDIA] Pvt Ltd.](https://tiimg.tistatic.com/images/l/2/logo_117023.jpg)

Send Inquiry

Send Inquiry